In the modern industrial landscape, where energy efficiency and optimal performance are paramount, forced draft coolers emerge as unsung heroes. These crucial components not only facilitate thermal regulation in a variety of processes but also play a significant role in enhancing operational efficiency across multiple sectors. This article explores the intricacies of forced draft coolers, their diverse applications, technical design considerations, and economic implications.

Understanding Forced Draft Coolers

The Mechanism of Forced Draft Cooling

At its core, a forced draft cooler consists of a fan that actively pushes air over a heat exchange surface, which is usually lined with metal fins. This design maximizes the surface area for heat transfer, allowing for rapid cooling of hot gases, liquids, or solids. The forced nature of the air movement distinguishes these coolers from their induced draft counterparts, which rely on the natural upward flow of hot air.

Key Components:

- Fan: This is the beating heart of the cooler, generating the necessary airflow to promote efficient heat transfer. The fan’s size and type (axial or centrifugal) significantly affect its performance.

- Heat Exchange Surface: Typically constructed from metals like aluminum or stainless steel for their excellent thermal conductivity, the fins increase the surface area for interaction between the hot medium and the cooling air.

- Housing: The housing contains the internal components and is designed to direct and optimize the airflow, often featuring aerodynamically designed shapes to reduce drag.

- Motors and Controls: These components regulate fan operation, allowing for adjustments based on real-time cooling needs, further enhancing energy efficiency.

Working Principle

When hot air or liquid enters the cooler, it passes through the heat exchange surface where it is met with a stream of cooler air. The thermal energy from the hotter substance is transferred to the cooling air, reducing the temperature of the fluid while increasing the air temperature. This process may also involve some degree of latent heat transfer if the cooling involves phase changes, such as condensation.

Приложения в различных отраслях промышленности

Forced draft coolers find a multitude of applications in various industrial sectors, where effective temperature management is critical.

Генерация электроэнергии

In power plants, forced draft coolers are crucial for cooling flue gases before they reach air pollution control devices, such as electrostatic precipitators or fabric filters. These coolers reduce the flue gas temperature, thus improving the efficiency of these devices while minimizing the formation of harmful emissions.

Химическая обработка

The chemical industry frequently uses forced draft coolers to manage the temperatures of reaction products. By cooling these products, manufacturers can reduce viscosity, making the materials easier to transport and process, and prevent overheating that could lead to safety issues or inefficient reactions.

Обработка металла

In metal processing, the cooling of hot metal products is vital before further manipulation or storage. Forced draft coolers ensure that the metals cool down swiftly, preventing deformation and oxidation while promoting safe handling practices.

Еда и напитки

The food and beverage industry utilizes forced draft coolers for applications such as cooling, pasteurization, and during the production of beverages or liquid food products. This cooling is essential to ensure product safety, prolong shelf life, and maintain quality.

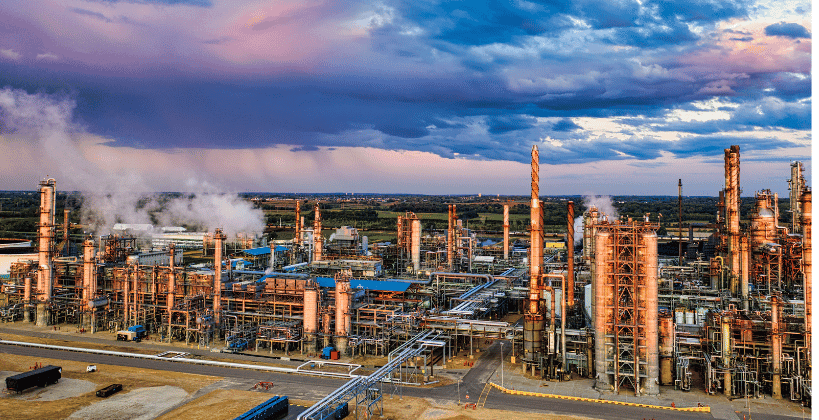

Нефть и газ

In the oil and gas sectors, forced draft coolers manage the temperatures of various fluids and gases, ensuring optimal performance across oil refining processes and preventing equipment overheating.

Economic Benefits of Forced Draft Coolers

The role of forced draft coolers extends beyond their technical applications; they also offer substantial economic benefits, which can be a game changer in capital-intensive industries.

Improved Equipment Efficiency

By managing the temperature of gases or liquids entering downstream processes, forced draft coolers enable equipment to operate within optimal parameters. For instance, in power generation, cooler flue gases enhance the performance of air pollution control devices, resulting in lower operational costs and higher throughput.

Сокращение расходов на техническое обслуживание

Operating equipment under high thermal stress can lead to significant wear and tear. Forced draft coolers mitigate this risk by maintaining lower operating temperatures, thus extending the lifespan of critical equipment. This translates to reduced maintenance and replacement costs, improving the overall bottom line for industries that rely on heavy machinery.

Energy Savings

In some instances, forced draft coolers can be designed to recover heat from the cooling process. This recovered energy can be repurposed for auxiliary processes, contributing to energy savings and overall operational efficiency. Through combined heat and power (CHP) systems, industries can realize significant cost savings on energy bills while enhancing their sustainability profiles.

Экологические преимущества

As industries strive for more eco-friendly operations, forced draft coolers contribute to this goal. By improving efficiencies and lowering energy consumption, these coolers help in reducing greenhouse gas emissions, making them a vital component in the pursuit of sustainable industrial practices.

Technical Considerations for Forced Draft Coolers

The efficiency and performance of forced draft coolers hinge upon several technical considerations that manufacturers and engineers must take into account during the design and installation phases.

Heat Transfer Requirements

One of the primary factors influencing the design of a forced draft cooler is the heat transfer capacity required. Calculating the necessary cooling load allows engineers to determine the appropriate size and surface area of the heat exchange elements. This requires knowledge of the fluid’s specific heat, flow rates, and the permissible temperature differential.

Airflow Design

Proper airflow is critical for optimal performance. The selection of fans needs careful consideration regarding size, power, and type (centrifugal vs. axial), depending on the air pressure requirements for efficiency. The design of the housing must complement airflow, minimizing turbulence and maximizing laminar flow through the heat exchange area.

Material Compatibility

Forced draft coolers must be built with materials compatible with the fluids being cooled to prevent corrosion, contamination, and degradation of both the cooler itself and the products. This often involves choosing corrosion-resistant metals and incorporating protective coatings where necessary.

Maintenance and Cleaning

Regular maintenance is essential for the smooth operation of forced draft coolers. Dust, dirt, and other particulates can accumulate on the heat exchange surfaces, impeding performance. Therefore, establishing a regular inspection and cleaning schedule can help maintain cooling efficiency and prolong the lifespan of the equipment.

Заключение

Forced draft coolers are indispensable components in a wide variety of industrial processes. By efficiently cooling hot gases and liquids, they enhance operational efficiency, reduce maintenance costs, and promote environmental sustainability. Understanding both the technical aspects and the economic implications of forced draft coolers is crucial for optimizing industrial operations. As industries continue to prioritize efficiency and environmental responsibility, the role of these essential cooling systems is likely to become even more significant. Investing in forced draft cooling technology may represent not just a technical improvement but also a strategic economic advantage across multiple sectors.

Would you like to explore specific applications or delve deeper into the design and performance aspects of forced draft coolers? They are critical, versatile components with much to offer the modern industrial environment.