Hybride filters

- Elektrostatische precipitators

- Achteruitrij-airbaghuizen

- Stoffilters

- Hybride elektrofilters

- Rookgasontzwaveling

- Koeler met geforceerde trek

- Schrobbers

- Gasreinigingsinstallaties

- Cyclonen

- Multiklonen

- VOC + Geurverwijderingssysteem

- Stofafzuigsysteem

- Rookafzuigsysteem

- Explosiebeveiligingsapparatuur

- Ventilatoren en blowers

- Afvalwaterbehandeling

- Lucht-lucht warmtewisselaar

Kantoren

HOOFDKANTOOR

Duitsland

-

Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Duitsland/Duitsland - +49 20534200990

REGIONAAL KANTOOR

Groot-Brittannië

-

Intensief filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Groot-Brittannië - +44 1922 628893

REGIONAAL KANTOOR

Verenigde Arabische Emiraten

-

Intensieve filter Himenviro Technologies FZE – LLC

Businesscentrum, Sharjah Publishing City Free Zone, Sharjah, VAE - +971-556074697

REGIONAAL KANTOOR

Indië

-

Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAAL KANTOOR

Indië

-

Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAAL KANTOOR

Indië

-

Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Hybride elektrofilters

Thuis » Oplossingen » Hybride filters

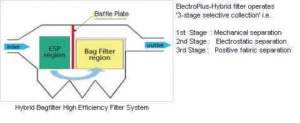

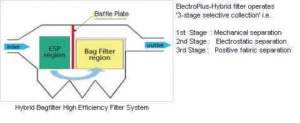

Onze 'Electro-Plus-Hybrid Filter'-technologie is een oplossingsprovider die gebruikmaakt van een filtersysteem dat statische elektriciteit op het fijnstof gebruikt voor een hogere opvangefficiëntie met minder drukval. Het lost het probleem van de toename van de drukval op dat vaak wordt waargenomen door verstopping van de zak door impregnatie van fijne stofdeeltjes, in het geval van een conventioneel zakfiltersysteem, wat de levensduur van de zak aanzienlijk verlengt. Het hybride filter is een zeer efficiënt en hoogwaardig complex filtersysteem waarin de stofdeeltjes van de Dendrite Structure Layer op het zakoppervlak de penetratie van microdeeltjes voorkomen en de verblindingsstatus van filterzakken verminderen, waardoor de filterefficiëntie van het hybride systeem wordt verbeterd. Het hybride filter is een zeer efficiënt en hoogwaardig complex filtersysteem waarin de stofdeeltjes van de Dendrite Structure Layer op het zakoppervlak de penetratie van microdeeltjes voorkomen en de verblindingsstatus van filterzakken verminderen, waardoor de filterefficiëntie van het hybride systeem wordt verbeterd.

Sollicitatie

Proces

Onze diensten

Casestudy

Veelgestelde vragen

1. What is a hybrid filter?

A hybrid filter is a device that cleans dirty air by combining two methods: electrostatic precipitation and fabric filtration. First, it uses electrical charges to capture large dust particles. Then, it uses fabric filters to catch smaller particles, making the air cleaner and safer to breathe.

2. How does a hybrid filter work?

A hybrid filter works in two steps. First, the electrostatic section charges and captures large dust particles from the air. Next, the air passes through fabric filters that trap the remaining fine particles. This two-step process ensures efficient removal of dust and pollutants from the air.

3. Why are hybrid filters used in industries?

Industries use hybrid filters to keep the air clean by removing dust and harmful particles produced during manufacturing. This helps protect workers’ health, reduces environmental pollution, and ensures compliance with air quality regulations.

4. What are the benefits of using a hybrid filter?

Hybrid filters offer several benefits:

- Hoge efficiëntie: They effectively remove both large and small particles from the air.

- Energy Savings: The combination of technologies reduces energy consumption compared to using separate systems.

- Kosteneffectief: They often require less maintenance and have longer lifespans, saving money over time.

5. In which industries are hybrid filters commonly used?

Hybrid filters are commonly used in industries such as:

- Cementproductie: To control dust emissions.

- Power Plants: To remove fly ash from flue gases.

- Steel Manufacturing: To capture metallic dust particles.

- Chemical Processing: To filter out hazardous airborne particles.

6. How does a hybrid filter compare to traditional filters?

Unlike traditional filters that use only one method, hybrid filters combine electrostatic and fabric filtration techniques. This combination allows them to capture a wider range of particle sizes more efficiently, leading to cleaner air and improved performance in industrial applications.

7. What maintenance is required for hybrid filters?

Maintaining a hybrid filter involves regular inspections to check for wear and tear, cleaning or replacing fabric filter bags as needed, and ensuring the electrostatic components are functioning properly. Following the manufacturer’s maintenance guidelines helps keep the system effective and extends its lifespan.

8. Can existing filtration systems be upgraded to hybrid filters?

Yes, many existing filtration systems, especially electrostatic precipitators, can be upgraded to hybrid filters. This upgrade enhances filtration efficiency without the need for completely new installations, making it a cost-effective solution for industries aiming to improve air quality.

9. Are hybrid filters environmentally friendly?

Hybrid filters are environmentally friendly because they effectively reduce the emission of harmful particles into the atmosphere. By capturing a broad range of pollutants, they help industries meet environmental regulations and contribute to cleaner air.

10. How do hybrid filters contribute to energy efficiency?

Hybrid filters contribute to energy efficiency by combining two filtration methods that work together to reduce the overall energy required for air cleaning. The initial electrostatic stage captures large particles with minimal energy, reducing the load on the subsequent fabric filter stage, which in turn operates more efficiently.