Temperature regulation is a critical aspect of industrial operations, as excessive heat can lead to equipment failure, reduced productivity, and safety hazards. Industrial cooling systems play a crucial role in maintaining optimal operating temperatures, ensuring machinery longevity, and enhancing energy efficiency. These systems are used across various industries, including manufacturing, power generation, chemical processing, and food production, where heat management is essential for smooth operations.

Advancements in industrial cooling technology have led to more energy-efficient and cost-effective solutions, minimizing environmental impact while improving performance. By selecting the right cooling system, businesses can reduce maintenance costs, enhance product quality, and comply with industry regulations.

How Industrial Cooling Systems Work

Industrial cooling systems function by dissipating excess heat generated by machinery, processes, and 산업 환경. They use various mechanisms such as air cooling, water cooling, and refrigerant-based cooling to regulate temperature effectively. These systems prevent overheating, ensuring continuous and efficient operation while protecting critical equipment from thermal damage.

The efficiency of an industrial cooling system depends on factors such as heat load, ambient temperature, fluid circulation, and system design. Modern cooling solutions incorporate advanced controls, energy-saving technologies, and eco-friendly refrigerants to optimize performance while minimizing environmental impact.

지금 우리와 연결하세요

Types of Industrial Cooling Systems

Industrial cooling solutions vary based on application requirements, cooling medium, and energy efficiency. The most common types of industrial cooling systems include:

- Air Cooling Systems: Use fans and heat exchangers to dissipate heat into the surrounding air. Ideal for applications with moderate heat loads.

- Water Cooling Systems: Utilize water as a heat transfer medium, providing efficient cooling for high-temperature industrial processes. Includes cooling towers, evaporative coolers, and water-cooled heat exchangers.

- Chiller Systems: Circulate refrigerants to absorb and remove heat, offering precise temperature control. Used in manufacturing, medical, and data center applications.

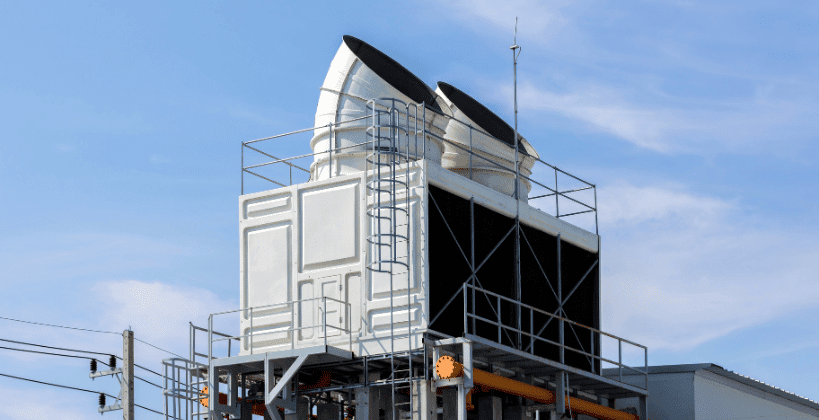

- Cooling Towers: Large-scale cooling solutions that evaporate water to dissipate heat, commonly used in power plants and industrial facilities.

- Oil Cooling Systems: Used in heavy-duty industrial machinery to maintain stable temperatures in hydraulic and lubrication systems.

- Hybrid Cooling Systems: Combine air and water cooling technologies for enhanced energy efficiency and environmental sustainability.

Applications of Industrial Cooling Systems

Industrial cooling solutions are essential in sectors where temperature control is critical to operational efficiency, product quality, and worker safety.

1. 제조 및 금속 가공

Machinery such as CNC machines, injection molding equipment, and metal furnaces generate significant heat. Cooling systems prevent overheating, ensuring precision and extended equipment life.

2. Power Generation & Energy Sector

Cooling towers and water-cooled heat exchangers regulate temperatures in power plants, preventing overheating of turbines, transformers, and generators.

3. Chemical & Petrochemical Industry

Chemical reactions produce large amounts of heat. Industrial cooling systems maintain stable temperatures in reactors, distillation units, and refining processes.

4. Food & Beverage Industry

Refrigeration and cooling systems help maintain optimal processing and storage conditions, preventing spoilage and ensuring food safety.

5. HVAC & Data Centers

Cooling systems in HVAC units and data centers regulate temperature and humidity, preventing overheating of computer servers and electronic equipment.

6. Aerospace & Automotive Industry

Wind tunnels, engine testing, and manufacturing plants rely on cooling systems to dissipate heat during production and testing.

7. Pharmaceutical & Biotechnology

Maintaining controlled environments is essential for drug formulation and bioprocessing. Chillers and climate-controlled rooms ensure precision temperature management.

당사의 솔루션 범위를 알아보세요:

Benefits of Industrial Cooling Systems

- Prevents Equipment Overheating: Reduces wear and tear, extending machinery lifespan and minimizing downtime.

- Enhances Energy Efficiency: Advanced cooling technologies optimize power consumption, reducing operational costs.

- Improves Product Quality: Maintains consistent temperature conditions, ensuring high-quality output in manufacturing and food processing.

- Compliance with Safety Standards: Meets industry regulations related to workplace safety, emissions, and environmental impact.

- Sustainability & Eco-Friendly Operation: Modern cooling systems use energy-efficient designs and eco-friendly refrigerants to reduce environmental footprint.

- Worker Safety & Comfort: Creates a controlled working environment by reducing excessive heat exposure in industrial facilities.

How to Choose the Right Industrial Cooling System

Selecting an industrial cooling system depends on multiple factors, including:

- Heat Load Requirements: Determines the cooling capacity needed to dissipate excess heat effectively.

- Cooling Medium: Air-based systems are suitable for low-heat applications, while water-cooled and refrigerant-based systems are ideal for high-heat processes.

- 에너지 효율성: Opt for systems with high energy efficiency ratings to reduce operational costs.

- 환경 영향: Consider eco-friendly options that use sustainable cooling technologies and minimize water consumption.

- System Integration: The cooling system should seamlessly integrate with existing industrial processes and automation controls.

- Maintenance & Longevity: Choose systems with minimal maintenance requirements and durable construction to ensure long-term reliability.

Why Choose Intensiv Filter Himenviro for Industrial Cooling Solutions?

Intensiv Filter Himenviro is a leading provider of industrial cooling systems designed to optimize temperature control, energy efficiency, and environmental sustainability. Our solutions cater to diverse industries, ensuring operational reliability and compliance with safety standards.

우리를 차별화하는 것은 무엇인가?

- Advanced Cooling Technology: Our systems incorporate cutting-edge cooling mechanisms for superior performance.

- 맞춤형 솔루션: Tailored cooling systems designed to meet industry-specific needs.

- Energy-Efficient Designs: Our solutions minimize power consumption while maximizing cooling efficiency.

- Durability & Reliability: Engineered for long-term operation in demanding industrial environments.

- 종합 지원: From installation to maintenance, we provide expert consultation and technical assistance.

결론

Industrial cooling systems are essential for maintaining optimal operating temperatures, preventing equipment failures, and ensuring workplace safety. From manufacturing to energy production, these systems play a crucial role in enhancing efficiency and product quality. With advancements in cooling technology, businesses can benefit from energy-efficient, eco-friendly solutions that minimize operational costs and environmental impact.

With Intensiv Filter Himenviro’s cutting-edge cooling solutions, industries can achieve superior performance, regulatory compliance, and long-term reliability. Investing in the right industrial cooling system is not just a necessity—it’s a strategic move toward sustainability, efficiency, and cost savings.