Air quality control is a critical concern for industrial facilities, and dust collector jets play a vital role in maintaining a clean and safe working environment. These systems efficiently remove airborne particulates, improving air quality and ensuring compliance with environmental regulations. The dust collector jet technology, widely used in various industries, offers an effective and automated solution for continuous dust removal.

How Dust Collector Jet Systems Work

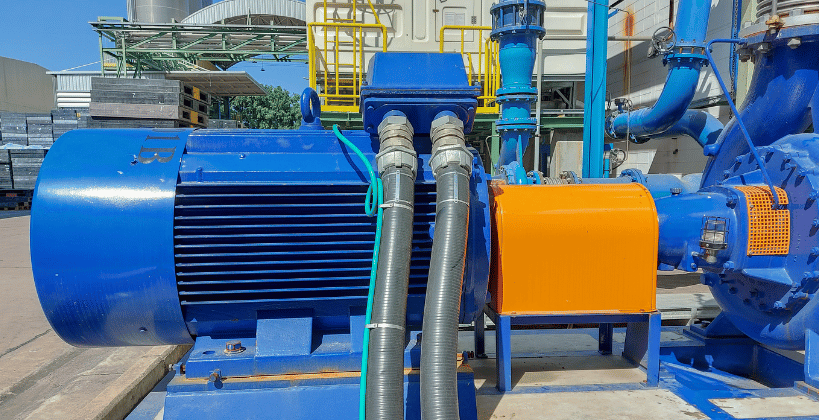

A dust collector jet operates using a pulse-jet cleaning system, which ensures high efficiency in capturing and removing dust particles from industrial processes. These systems primarily consist of a filtration unit, pulse valves, compressed air reservoirs, and dust disposal mechanisms.

The working mechanism involves:

- Dust-Laden Air Entry – Contaminated air is drawn into the dust collector through an inlet duct. Larger particles settle in a pre-collection chamber, while finer dust moves toward the filtration unit.

- Filtration Process – The air passes through filter bags or cartridges, where fine particulates are trapped, allowing clean air to exit.

- Pulse-Jet Cleaning – Periodic bursts of compressed air are released into the filter media, dislodging accumulated dust. This self-cleaning mechanism ensures uninterrupted airflow and extended filter life.

- Dust Disposal – The dislodged dust settles at the bottom of the collector and is either manually removed or automatically discharged into a collection bin.

Pulse-jet dust collectors offer superior efficiency, allowing industries to maintain optimal air quality while reducing maintenance efforts.

당사의 솔루션 범위를 알아보세요:

Types of Dust Collector Jet Systems

Dust collector jets are available in different configurations to suit various industrial needs. The primary types include:

- Baghouse Dust Collectors – These systems use fabric filter bags to trap particulates. They are ideal for high-volume dust collection in industries such as cement manufacturing and metalworking.

- Cartridge Dust Collectors – Equipped with pleated filters, these collectors offer higher filtration efficiency and are widely used in pharmaceutical and food processing industries.

- Cyclone Dust Collectors – These pre-separators remove large particles before the filtration process, enhancing overall efficiency.

- Modular Pulse-Jet Collectors – Designed for flexibility, these collectors allow easy expansion to accommodate growing industrial needs.

- Portable Dust Collectors – Compact and mobile units suitable for localized dust collection in smaller workspaces.

The choice of dust collector jet depends on factors such as dust type, volume, particle size, and industry-specific requirements.

Key Applications of Dust Collector Jet Systems

Dust collector jets are essential in numerous industries where air pollution control is a priority. These systems help in compliance with workplace safety and environmental regulations while ensuring smooth operations.

1. Manufacturing and Metal Processing

Industries such as welding, grinding, and cutting generate fine metallic particulates that pose health risks. Dust collectors effectively capture these particles, preventing respiratory issues and machinery damage.

2. Cement and Construction Industry

Cement production involves significant dust generation, which can lead to environmental pollution and health hazards. Dust collector jets help in maintaining compliance with emission standards.

3. Food Processing and Pharmaceuticals

Strict hygiene standards in these industries require efficient dust collection to prevent contamination. Pulse-jet collectors ensure safe handling of powdered substances, reducing health risks.

4. Woodworking and Furniture Manufacturing

Sawing, sanding, and cutting wood produce substantial airborne dust. Dust collector jets help in maintaining a dust-free environment, improving worker safety and product quality.

5. Mining and Quarrying

Extraction and processing of minerals generate heavy dust emissions. Efficient dust collection systems are crucial to protect workers and minimize environmental impact.

6. Power Plants and Boilers

Coal-fired power plants release fine particulate matter that must be controlled. Dust collector jets enhance air quality by capturing and filtering combustion byproducts.

7. Chemical and Petrochemical Industry

Handling of powdered chemicals generates hazardous airborne particles. Industrial dust collectors ensure compliance with strict safety regulations.

Advantages of Dust Collector Jet Systems

- 높은 여과 효율: Captures fine particulates, ensuring cleaner air and improved workplace conditions.

- Continuous Operation: The pulse-jet cleaning mechanism maintains consistent airflow, reducing downtime.

- 에너지 효율성: Modern dust collectors are designed to optimize airflow and minimize energy consumption.

- 낮은 유지 관리: Automated cleaning and durable filters extend operational life, lowering maintenance costs.

- 환경 준수: Meets stringent air quality regulations, reducing emissions and improving sustainability.

- Worker Safety: Prevents exposure to harmful dust, minimizing respiratory diseases and long-term health risks.

지금 우리와 연결하세요

Factors to Consider When Choosing a Dust Collector Jet

Selecting the right dust collector for an industrial setting requires careful evaluation of several factors:

- Dust Type and Particle Size: Understanding the properties of the dust being collected ensures the right filter media selection.

- 공기 흐름 요구 사항: Determining the correct airflow (measured in cubic feet per minute) ensures effective dust capture.

- Filter Efficiency: High-quality filter bags or cartridges enhance performance and longevity.

- Space and Installation Constraints: Available space and ductwork configuration impact the choice of dust collector.

- 규정 준수: Meeting industry-specific emission standards is crucial for avoiding penalties and maintaining operational integrity.

- 유지 보수 필요 사항: Choosing a system with automated cleaning features reduces labor costs and enhances efficiency.

Why Choose Intensiv Filter Himenviro for Dust Collector Jets?

Intensiv Filter Himenviro is a trusted provider of high-performance dust collection solutions, offering advanced jet pulse dust collectors tailored for diverse industrial applications. Our expertise in air pollution control ensures that our systems provide reliable performance, energy efficiency, and regulatory compliance.

Key Features of Our Dust Collector Jet Systems

- Advanced Filtration Technology: Our systems utilize state-of-the-art filter media for maximum efficiency.

- Custom-Designed Solutions: Tailored dust collectors designed to meet industry-specific needs.

- Energy-Saving Designs: Optimized airflow systems reduce power consumption and operational costs.

- 내구성 및 신뢰성: Built with high-quality materials to withstand harsh industrial conditions.

- 종합 지원: Expert consultation, installation, and maintenance services ensure hassle-free operation.

결론

Dust collector jets are indispensable for industrial air quality management, ensuring the efficient removal of airborne particulates and maintaining compliance with environmental standards. Their application across diverse industries, from manufacturing to power generation, highlights their importance in creating a healthier work environment. Intensiv Filter Himenviro provides cutting-edge dust collection solutions, offering high-performance systems that deliver superior efficiency, reliability, and sustainability.

Investing in the right dust collector jet enhances air quality, protects worker health, and optimizes operational efficiency, making it a crucial component of modern industrial air pollution control strategies.