ProJet CIP Cleaning in Place Filter

Special Feature of the round Filter ProJet CIP

- Optimized geometry with a significantly reduced exhaust velocity between the filter bags that can be offered by a length of up to 8 m

- Reducing the number of mounting parts due to a longer filter bags, which leads to a reduction of the compressed air and CIP washing liquid?

- New development of clean gas chamber from a hygienic point

- Reduction of installation parts in the clean gas range and thus additional reduction in maintenance time

- No special tools for assembly / disassemble, maintenance and service necessary

- Equipped with ProTex CIP filter media that has been optimized for perfect wash-ability, short drying times and excellent clean-ability.

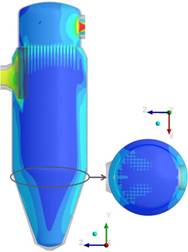

Cleaning system for the Process Filter ProJet Mega

Crucial importance for the energy-efficient operation of a bag filter system has the injector system with which the jet pulse is generated for the regeneration of the filter media. Intensiv-Filter has developed the Coanda injector and patented. The Coanda injector takes advantage of the so-called Coanda effect in which the beam follows a curved surface. This result in a maximum intensity of cleaning is achieved and accomplished simultaneously efficient separation of the filter cake from the filter medium.

The cleaning control of the new process filter ProJet mega via microprocessor technology and fieldbus systems. Intensiv-Filter sets for a long time tested and patented JetBus controller that regulates the cleaning pressure. The timing of the pressure pulses is varied depending on the requirement. Optionally, a fixed timing, or a differential pressure control can be applied with variable cycle times.

Product Recovery with the ProJet CIP