The Importance of Dust Collection in Industrial Processes:

Dust can have a multitude of negative consequences in industrial settings. Here’s why effective dust collection is crucial:

- Air Quality and Worker Health: Dust particles can irritate the respiratory system, leading to health problems like asthma and bronchitis. Efficient dust collection ensures cleaner air, promoting worker health and well-being.

- Equipment Protection: Dust can accumulate on machinery components, causing wear and tear, reducing efficiency, and increasing maintenance costs. Effective dust collection protects equipment, extending its lifespan and minimizing downtime.

- Explosion Prevention: In some cases, dust particles suspended in the air can create a hazardous environment. Certain types of dust are highly flammable and can ignite if present in sufficient concentrations. Dust collection systems mitigate this risk by preventing dust accumulation and potential explosions.

- Environmental Compliance: Many industries are subject to regulations concerning air quality emissions. Dust collection systems ensure compliance with these regulations, minimizing environmental impact.

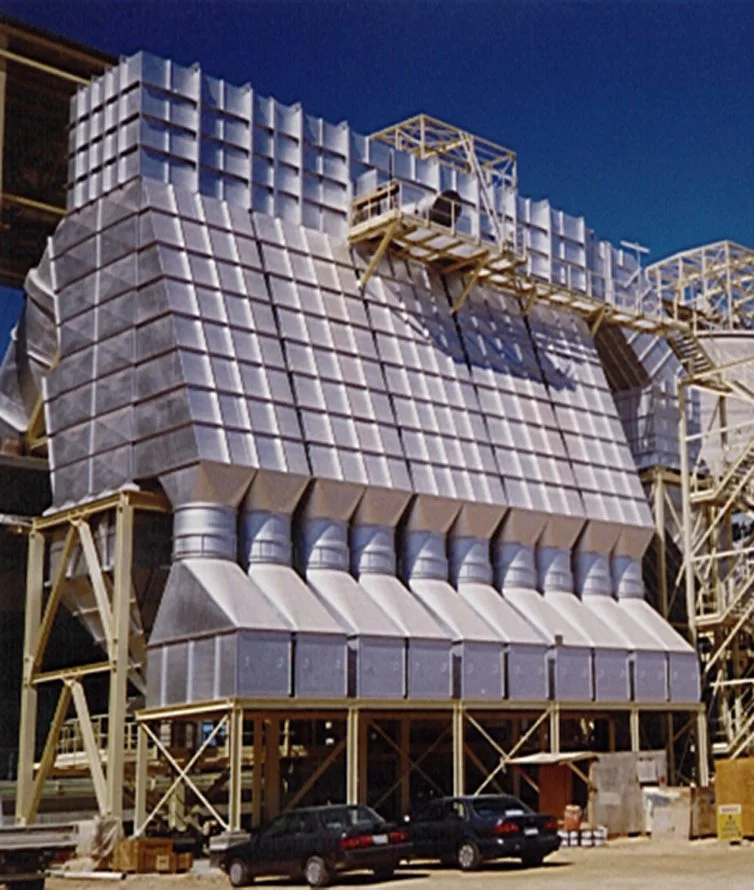

Why Reverse Air Bag Houses are a Preferred Choice:

Traditional bag houses have served as a mainstay in dust collection for many years. However, RABHs offer distinct advantages that make them a preferred choice in many industrial applications:

- Gentle Cleaning Mechanism: Unlike traditional bag houses that rely on forceful bursts of compressed air for cleaning, RABHs employ a gentler reverse air cleaning method. This method minimizes stress on the filter media, leading to longer filter bag life and reduced maintenance requirements.

- High Dust Collection Efficiency: RABHs achieve high dust collection efficiency through a combination of factors like cake filtration (dust accumulating on the filter media itself contributes to capturing finer particles) and the effectiveness of the reverse air cleaning in dislodging dust without disrupting the cake.

- Reduced Energy Consumption: The reverse air cleaning method in RABHs utilizes a lower pressure air stream compared to the compressed air used in traditional bag houses. This translates to significant energy cost savings over time.

- Suitable for High-Temperature Applications: Certain RABH designs can accommodate high-temperature applications due to the use of heat-resistant filter media. This makes them ideal for processes like wood drying or metalworking.

- Gentle on Sensitive Dusts: The low-pressure cleaning is suitable for handling delicate or sticky dust materials that might be damaged by harsher cleaning methods used in traditional bag houses.

By understanding the advantages of RABHs, industrial facilities can make an informed decision about their dust collection needs.

Filter Media in Reverse air bag houses (RABHs): A Focused Look

Here’s a concise breakdown of filter media selection in RABHs:

Types of RABH:

- Woven Fabrics: Strong, stable, handle high dust loads and temperatures (polyester, Nomex®). Less efficient for fine dust.

- Non-Woven Fabrics: Capture fine particles effectively due to smaller pores (microfibers, fiberglass). Less durable, not ideal for high temperatures or abrasion.

- Composite Media: Combines benefits (woven outer layer for strength, non-woven inner layer for efficiency).

Choosing the Right Media:

- Dust Characteristics: Size, shape, abrasiveness, moisture content all play a role. Finer dust needs smaller pores, abrasive dust might require stronger woven fabrics.

- Operating Temperature: The media must withstand process temperatures.

- Desired Efficiency: The required dust capture level dictates pore size and filtration mechanism selection.

- Chemical Compatibility: Ensure media compatibility with any process chemicals in the dust stream.

- Cost and Maintenance: Consider initial cost vs. replacement frequency.

This provides a clear and concise explanation of filter media selection in RABHs, focusing on key points without excessive detail.

Advantages : A Deeper Dive into RABH

Reverse Air Bag Houses (RABHs) offer several compelling advantages over traditional bag house designs, making them a preferred choice for many industrial dust collection applications. Let’s delve deeper into these benefits:

1. Lower Energy Consumption:

- The RABH Difference: Unlike pulse jet bag houses that rely on bursts of compressed air for cleaning, RABHs utilize a low-pressure reverse air flow. This significantly reduces the energy required for the cleaning process. Compressed air generation can be a substantial energy consumer in traditional systems.

- Cost Savings: The lower energy consumption of RABHs translates to significant cost savings over time, especially in facilities that operate continuously. This can lead to a faster return on investment (ROI) for the RABH system.

- Environmental Impact: Reduced energy consumption also translates to a lower environmental footprint. RABHs contribute to a more sustainable operation by minimizing their contribution to greenhouse gas emissions.

- Gentle Touch, Powerful Results: The reverse air cleaning method in RABHs employs a lower pressure but continuous airflow compared to the high-pressure blasts used in pulse jet systems. This gentle approach effectively dislodges dust particles from the filter media without damaging the fibers.

- Maintaining Filter Integrity: Preserving the integrity of the filter media is crucial for sustained dust collection efficiency. The gentler cleaning action of RABHs minimizes fiber breakage and allows the filter media to last longer.

- Minimizing Wear and Tear: The low-pressure reverse air cleaning in RABHs minimizes wear and tear on the filter media. This translates to less frequent maintenance needs compared to traditional bag houses that experience harsher cleaning methods.

- Easier Maintenance: RABH designs often incorporate features that simplify maintenance procedures. For example, some RABHs have easy access hatches for filter bag inspection and replacement.

- Lower Labor Costs: Reduced maintenance requirements translate to lower labor costs associated with system upkeep. Additionally, easier maintenance procedures can save time and resources.

- Material Matters: Certain RABH designs can accommodate high-temperature environments due to the use of specialized filter media. These media are constructed from heat-resistant materials like Nomex® or Ryton® that can withstand high operating temperatures without compromising performance or integrity.

- Process Versatility: The ability to handle high temperatures expands the applicability of RABHs to various industrial processes.

- Delicate Approach: The low-pressure cleaning mechanism in RABHs makes them suitable for handling delicate or sticky dust materials. These materials might be damaged by the harsher cleaning methods employed in pulse jet bag houses, where high-pressure air blasts can break down the dust or cause it to adhere more firmly to the filter media.

- Preserving Material Integrity: RABHs can effectively collect dust from various materials like:

Pharmaceutical Powders: Ensuring product quality and worker safety.

Food Processing Dusts: Maintaining hygiene and preventing product contamination.

Fibrous Materials: Effectively capturing dust without damaging the fibers.

By understanding these advantages, industrial facilities can make an informed decision when choosing a dust collection system. RABHs offer a compelling combination of energy efficiency, high cleaning efficiency, reduced maintenance, and versatility, making them a valuable asset for various industrial applications.

Conclusion: Make the right choices.

Reverse air bag houses (RABHs) have established themselves as a powerful solution for industrial dust collection. They offer a multitude of benefits that translate to cleaner air, improved efficiency, and cost savings.

Key Takeaways:

- High Dust Collection Efficiency: RABHs achieve exceptional efficiency through cake filtration and a gentle cleaning mechanism that preserves filter media integrity.

- Reduced Energy Consumption: The low-pressure reverse air cleaning significantly lowers energy demands compared to traditional compressed air systems.

- Minimized Maintenance: The gentle cleaning action translates to less wear and tear on the filter media, leading to reduced maintenance requirements and extended filter life.

- High-Temperature Applications: Specific RABH designs can handle high temperatures due to the use of heat-resistant filter media.

- Suitable for Sensitive Dusts: The low-pressure cleaning is ideal for delicate or sticky dust materials that might be damaged by harsher cleaning methods.

The Right Choice for Your Needs:

If your industrial process demands efficient dust collection, RABHs are a strong contender. They are particularly well-suited for scenarios involving:

- High operating temperatures

- Handling of sensitive dust materials

- Energy efficiency concerns

Taking the Next Step:

For facilities seeking a cleaner, more efficient dust collection solution, RABHs offer a compelling option. Consulting with a qualified air filtration specialist can help you determine if a RABH system is the ideal fit for your specific needs and industrial processes. By exploring the advantages of RABHs, you can take a significant step towards a healthier work environment, improved equipment protection, and a more sustainable operation.