In the industrial world, air pollution is a persistent problem, with many sectors facing increasing pressure to meet stringent environmental standards. High-emission industries like power generation, steel production, cement manufacturing, and chemical processing are some of the most significant contributors to air pollution. These industries produce a variety of harmful pollutants, including sulfur dioxide (SO₂), nitrogen oxides (NOx), particulate matter, volatile organic compounds (VOCs), and hazardous air pollutants (HAPs).

Traditionally, wet scrubbers have been one of the most widely used technologies for controlling air pollution by removing particulate matter and harmful gases from flue gases. Wet scrubbers use liquid (usually water or an alkaline solution) to capture and neutralize pollutants. However, despite their effectiveness, traditional wet scrubbers face challenges in improving pollutant removal efficiency and reducing water consumption.

Plasma wet scrubbers present a new frontier in air pollution control by using plasma technology to enhance pollutant removal rates and improve the overall efficiency of traditional wet scrubbing systems. This innovation addresses two of the most significant drawbacks of traditional wet scrubbers—inefficient pollutant removal of certain gases and high water consumption—making plasma-assisted systems more suitable for industries with stringent emission standards.

In this blog, we will explore the principles of plasma-enhanced wet scrubbers, their advantages over traditional systems, and how Intensiv-Filter Himenviro plays a crucial role in advancing these technologies to help industries meet regulatory requirements while minimizing environmental impact.

Temukan Berbagai Solusi Kami:

Understanding Plasma Technology in Air Pollution Control

Plasma technology refers to the use of ionized gas (plasma) to initiate chemical reactions that break down or neutralize pollutants. Plasma is the fourth state of matter, consisting of a mixture of ions, electrons, and neutral particles. It is generated by applying a strong electric field to a gas, creating highly reactive radicals and ions that can react with pollutants and transform them into less harmful substances.

In the context of air pollution control, plasma technology has been used to assist in the removal of pollutants like NOx, VOCs, and even particulate matter. Plasma-assisted wet scrubbers take advantage of plasma’s reactivity to enhance the chemical reactions in the scrubber, improving the efficiency of pollutant capture and removal.

Traditional Wet Scrubbers: How They Work

Wet scrubbers are widely used for their ability to remove both particulate matter and gaseous pollutants from industrial emissions. They function by bringing flue gases into contact with a liquid, usually water or an alkaline solution. The pollutants are absorbed into the liquid, where they react chemically and are neutralized or captured.

There are various types of wet scrubbers, including:

- Menara Semprot: These use sprays of liquid to remove pollutants from the flue gas stream

- Scrubber Venturi: High-velocity gas is forced through a narrow throat, where it contacts the liquid, resulting in high-efficiency pollutant removal.

- Mesin Penggosok Tempat Tidur Kemasan: The gas flows through a bed of packing material, where it contacts the scrubbing liquid, enhancing the absorption of pollutants.

While wet scrubbers are effective at removing particulates and some soluble gases like sulfur dioxide, they are not as effective at removing non-soluble gases like nitrogen oxides (NOx) and VOCs. Additionally, traditional wet scrubbers consume large amounts of water, which poses challenges in water-scarce regions or industries seeking to reduce water consumption.

The Need for Plasma-Enhanced Wet Scrubbers

Plasma-enhanced wet scrubbers offer a solution to the limitations of traditional systems by integrating plasma technology to enhance the pollutant removal process. The plasma generates reactive species like hydroxyl radicals (OH), atomic oxygen (O), and ozone (O₃), which can break down pollutants more efficiently than simple liquid absorption.

The key benefits of plasma-assisted systems include:

- Higher Pollutant Removal Efficiency: Plasma enhances the breakdown of pollutants, especially for non-soluble gases like NOx and VOCs, which are typically harder to remove with conventional wet scrubbers. The plasma reactions can convert these harmful gases into less harmful byproducts or make them more soluble, improving their capture rate in the scrubber.

- Reduced Water Consumption: Traditional wet scrubbers require large volumes of water to maintain effective pollutant removal. Plasma-enhanced systems reduce the dependency on water by improving the chemical reactions between the gas and liquid phases. This allows industries to achieve the same level of pollutant removal with less water, making the technology more sustainable.

- Peningkatan Efisiensi Energi: Plasma-assisted systems can operate at lower temperatures compared to other pollutant control methods, reducing the energy required for operation. This energy efficiency can lead to significant cost savings for industries with large-scale emissions.

- Keserbagunaan: Plasma technology can be adapted to remove a wide range of pollutants, including NOx, SO₂, VOCs, and particulate matter. This makes plasma-enhanced wet scrubbers suitable for diverse industries with different emission profiles.

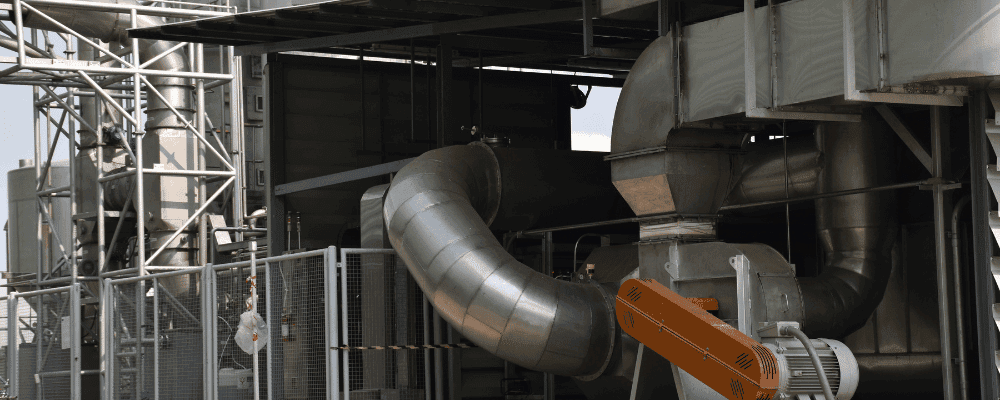

How Plasma-Enhanced Wet Scrubbers Work

Plasma-enhanced wet scrubbers integrate wet scrubbing techniques with the benefits of plasma reactions to enhance pollutant removal. In this process, the flue gas first undergoes pre-treatment as it enters the scrubber and is exposed to a plasma field. The high-energy plasma ionizes the gas, generating reactive radicals and ions that initiate the breakdown of pollutants, converting them into more soluble or less harmful substances. Following this, the pre-treated flue gas comes into contact with the scrubbing liquid, where the plasma-enhanced reactions facilitate easier dissolution or chemical reactions of the pollutants with the liquid. This combination of plasma reactions and liquid absorption improves the efficiency of capturing both particulate matter and gaseous pollutants. The scrubbing liquid neutralizes or dissolves these pollutants, which are subsequently removed from the system. Additionally, the use of plasma enhances the chemical reactions, reducing the amount of liquid needed for high pollutant removal rates, thus lowering water consumption and making the system more environmentally sustainable.

Hubungi kami sekarang

Advantages of Plasma Wet Scrubbers for High-Emission Industries

Higher Compliance with Emission Standards

Plasma-assisted wet scrubbers can achieve higher pollutant removal rates than traditional systems, making it easier for industries to comply with strict environmental regulations. This is particularly important in regions where NOx and VOCs are heavily regulated, such as the European Union and the United States.

Cost Savings on Water Usage

Industries operating in water-scarce regions or those looking to reduce their environmental footprint can benefit from the reduced water consumption of plasma-enhanced systems. By using plasma to enhance pollutant breakdown, these systems require less liquid to operate effectively, lowering the overall water demand.

Adaptability to Various Pollutants

The versatility of plasma technology allows industries to tackle a broad range of pollutants, including difficult-to-remove gases like NOx, VOCs, and heavy metals. This adaptability makes plasma-enhanced wet scrubbers a viable solution for industries with complex emission profiles, such as chemical plants and waste incinerators.

Efisiensi Energi

Plasma-enhanced wet scrubbers operate at lower temperatures than many other air pollution control technologies, resulting in lower energy consumption. This energy efficiency can reduce operational costs, particularly for industries that generate large volumes of flue gases.

Sustainability and Environmental Impact

By improving the efficiency of pollutant removal and reducing water and energy consumption, plasma-enhanced wet scrubbers contribute to the overall sustainability of industrial operations. This technology helps industries reduce their environmental impact, improve air quality, and contribute to a cleaner and more sustainable future.

How Intensiv-Filter Himenviro is Driving Innovation in Plasma Wet Scrubbing Technologies

Intensiv-Filter Himenviro offers tailored plasma-enhanced wet scrubbing solutions that are specifically designed to meet the unique emission control requirements of a wide range of industries, including power generation, cement manufacturing, steel production, and chemical processing. Understanding that each industry faces distinct challenges, the company ensures that its systems are customized to deliver optimal results in pollutant removal, water conservation, and operational cost savings. These solutions are engineered to meet the stringent emission reduction targets set by regulatory bodies while ensuring efficient resource utilization, making them a preferred choice for industries looking to enhance their environmental performance.

The successful integration of plasma technology into wet scrubbing systems requires a deep level of technical expertise, which Intensiv-Filter Himenviro brings through its experienced engineering teams. These experts have extensive knowledge in designing and implementing plasma-enhanced systems, ensuring they are perfectly optimized for the specific processes of each industrial client. By seamlessly incorporating plasma technology into their solutions, Intensiv-Filter Himenviro allows its clients to achieve higher pollutant removal rates without causing any disruption to existing operations, ensuring smooth and efficient functioning across all sectors.

At the heart of Intensiv-Filter Himenviro’s mission is a strong commitment to sustainability. The company is dedicated to helping industries minimize their environmental footprint by offering advanced technologies that reduce water and energy consumption while maximizing the efficiency of emission control. With its plasma-enhanced wet scrubbing systems, the company is not only helping industries meet their regulatory and environmental targets but also contributing to the broader goal of improving air quality and conserving natural resources.

In addition to providing cutting-edge technology, Intensiv-Filter Himenviro ensures long-term support and maintenance for all its systems. From the initial installation and commissioning stages to regular maintenance and necessary upgrades, the company offers comprehensive technical support to guarantee the continued high performance of its systems. This long-term partnership helps industries maintain compliance with evolving environmental standards while ensuring that their plasma-enhanced wet scrubbing systems operate at peak efficiency throughout their lifespan.

Conclusion: The Future of Air Pollution Control with Plasma-Enhanced Wet Scrubbers

As industries face increasing pressure to reduce their emissions and operate more sustainably, plasma-enhanced wet scrubbers offer a promising solution for improving air pollution control. By combining the proven effectiveness of wet scrubbing with the power of plasma technology, these systems can achieve higher pollutant removal rates, reduce water consumption, and operate more efficiently than traditional systems.

Intensiv-Filter Himenviro is leading the way in advancing plasma-enhanced wet scrubbing technologies, providing customized solutions for high-emission industries worldwide. By investing in innovative technologies and sustainable practices, Intensiv-Filter Himenviro is helping industries meet stringent emission standards while minimizing their environmental impact.

As the demand for cleaner air and more sustainable industrial practices continues to grow, plasma-enhanced wet scrubbers represent a key technology in the fight against air pollution and climate change. With the expertise and support of Intensiv-Filter Himenviro, industries can confidently adopt these advanced systems to achieve their emission control goals and contribute to a cleaner, healthier future.