Injector Systems for Efficient Cleaning

A crucial feature falls to the injector system with which the pulse jet filter is cleaned. The cleaning has to be done so that the filter cake over the entire length of hose detaches completely. In parallel, the repulse of the medium on the support cage (“Carpet beating effect”) should be minimized by appropriate modulation of the pressure curve.

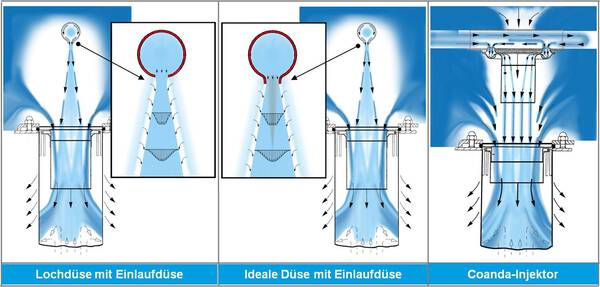

Many injector systems consist of a blowpipe simple as drilling hole type nozzle, a so-called Nozzle Injector. A significant improvement in the conversion of the static pressure energy in the blowpipe in a directed jet of compressed air is achieved by extruding the nozzle to a “ideal nozzle”.

Developed by intensive filter under the name Coanda injector cleaning system utilizes the so-called Coanda effect in which the compressed air emerges from an annular gap and is guided over a curved surface. In addition to the more efficient cleaning, the reduction of the clean gas dust emissions due to a more gentle cleaning and another positive side effect.