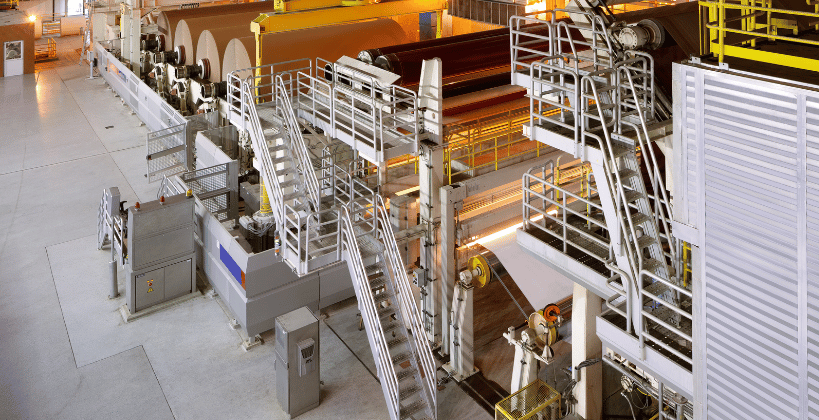

The Early Stages: Pulp Preparation

Our journey begins in the pulping process, where wood chips undergo a transformation into a watery slurry. This initial step, whether mechanical, chemical, or a combination of both, generates unwanted guests – wood fragments, bark, and other contaminants. Here, filtration technologies like screens and hydrocyclones come into play.

- Screens: These act as a sieve with varying mesh sizes, allowing the desired pulp fibers to pass through while capturing larger contaminants. They are often the first line of defense, ensuring a cleaner starting point for the subsequent stages.

- Hydrocyclones: These ingenious devices utilize centrifugal force to separate solids (impurities) from the liquid pulp slurry. The swirling motion within the hydrocyclone pushes heavier contaminants outwards, where they are collected for disposal, while the lighter pulp fibers remain suspended in the inner core and exit for further processing.

Refining the Pulp: Stock Preparation

Following the pulping process, the pulp slurry undergoes stock preparation to refine its properties and ensure optimal paper quality. This stage involves filtration systems, such as pressure or vacuum filters, which meticulously remove impurities. These impurities include dirt particles that can cause blemishes, shives (unbroken fiber bundles) that affect smoothness and printability, and other contaminants that can compromise the paper’s overall strength, texture, or appearance. By effectively eliminating these unwanted elements, filtration plays a vital role in producing high-quality paper products.

Maintaining Clean Water: White Water Recycling

Sustainability is a paramount concern for the paper industry, and water conservation plays a pivotal role in achieving this goal.

Paper mills recycle a substantial volume of process water, commonly referred to as “white water,” which contains a mixture of fibers, fillers, and other contaminants from previous production cycles. To maintain water quality and prevent damage to equipment, advanced filtration systems are employed. These systems utilize technologies such as microfiltration, which employs membranes with minuscule pore sizes to capture microscopic impurities while allowing clean water to pass through. Additionally, self-cleaning filters offer automated contaminant removal without manual intervention, minimizing downtime and maintenance requirements. By effectively purifying white water, paper mills significantly reduce their reliance on freshwater resources, thereby mitigating their environmental impact and contributing to a more sustainable future.

Enhancing the Surface: Coating Filtration

Paper coatings add specific properties like gloss, printability, and water resistance. These coatings typically contain pigments, binders, and fillers. Filtration ensures these components are free from impurities, resulting in a smooth and uniform coating on the final paper product. Here, specialized filter media or membrane filtration technologies might be utilized for precise separation:

- Specialized Filter Media: Filter media can be designed with specific pore sizes and materials to target the size and type of contaminants present in coating formulations. This ensures optimal removal of impurities without compromising the desired coating properties.

- Membrane Filtration: Advanced membrane filtration technologies offer even finer separation capabilities. They are particularly useful for high-performance coatings or applications requiring exceptionally smooth surfaces.

Chemical Management: Filtration's Role

The papermaking process relies on various chemicals, from bleaching agents to sizing agents that enhance paper strength. Filtration plays a vital role here as well, ensuring the quality of these chemicals by removing impurities. Here’s how filtration benefits chemical management:

- Improved Efficiency: By removing impurities that can interfere with chemical reactions, filtration ensures that these chemicals function optimally during paper formation.

- Reduced Waste: Clean chemicals minimize the risk of reactions producing unwanted byproducts, leading to less waste generation.

- Enhanced Paper Quality: Clean chemicals contribute to consistent and predictable paper properties.

Filtration not only ensures the effectiveness of the chemicals but also protects downstream equipment from potential damage caused by impurities.

Discover Our Range of Solutions:

Challenges and Solutions: Overcoming Filtration Hurdles in Pulp and Paper

The pulp and paper industry presents unique challenges for filtration due to the nature of the materials involved. Here’s a closer look at some common hurdles and their solutions:

High Solids Content

Pulp slurries often present a significant challenge in filtration due to their high solid content. This can lead to rapid filter clogging and reduced efficiency. To address this issue, various strategies are employed. Self-cleaning filters, equipped with automated mechanisms, continuously remove captured solids, ensuring uninterrupted operation. Additionally, pressure filters, designed to withstand the demanding conditions of pulp and paper processing, are capable of handling higher solid loads. Furthermore, selecting filter media with larger pore sizes and increased dirt-holding capacity can help mitigate clogging problems, promoting efficient and effective filtration.

Abrasive Particles

Abrasive particles such as sand or mineral impurities pose a significant threat to filtration equipment. To safeguard these systems, several measures can be implemented. The use of robust filter media, constructed from abrasion-resistant materials, is crucial. Regular inspection and maintenance are essential to identify and address wear and tear before it leads to catastrophic equipment failure. Additionally, hydrocyclones can be employed as a pre-filtration stage to remove larger abrasive particles, thereby reducing the burden on subsequent filters and prolonging their lifespan.

Fiber Clogging

Fine fibers pose a significant challenge to filtration processes, as they can penetrate filter media and reduce filtration efficiency. To mitigate this issue, careful consideration of filter media selection is crucial. Utilizing filter media with appropriately sized pores can help prevent fiber penetration and maintain optimal filtration performance. Regular backwashing is essential for removing trapped fibers and restoring filter capacity. Additionally, the incorporation of filter aids into the pulp slurry can enhance filter cake formation and reduce the likelihood of fiber penetration, thereby ensuring efficient and effective filtration.

Biofouling

Biofouling, the accumulation of microorganisms on filter surfaces, can significantly impair filtration performance. This phenomenon can lead to reduced flow rates, increased pressure drops, and even complete blockage of the filter. To prevent biofouling and maintain optimal filtration efficiency, several strategies can be employed. Regular cleaning and disinfection are crucial for removing accumulated microorganisms and preventing their further growth. This can be achieved through physical cleaning methods or the use of chemical disinfectants. Additionally, biocidal agents, which are chemicals designed to kill or inhibit microbial growth, can be added to the process fluid to control biofouling. Finally, ultraviolet (UV) light technology can be utilized to inactivate microorganisms on the filter surface. UV radiation damages the DNA of microorganisms, rendering them unable to reproduce. By implementing these preventive measures, it is possible to minimize biofouling and ensure the long-term performance and reliability of filtration systems.

Energy Efficiency and Sustainability

Advanced Filtration Technologies

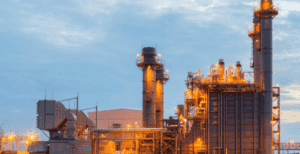

Intensiv-Filter Himenviro: A Partner in Pulp and Paper Filtration

Intensiv-Filter Himenviro is a leading provider of industrial filtration solutions, specializing in addressing the unique challenges faced by the pulp and paper industry. Their expertise lies in designing, manufacturing, and installing high-performance filtration systems that are tailored to meet the specific needs of paper mills.

Recognizing the diverse range of contaminants and operating conditions within the pulp and paper sector, Intensiv-Filter Himenviro offers a comprehensive suite of filtration technologies. From traditional bag filters and electrostatic precipitators to advanced wet scrubbers and hybrid systems, they provide solutions that effectively capture and remove particulate matter, gaseous pollutants, and odors.

Their team of experienced engineers and technicians collaborates closely with paper mills to understand their unique requirements and develop customized filtration solutions. By leveraging advanced technologies and materials, Intensiv-Filter Himenviro ensures that their systems deliver optimal performance, efficiency, and compliance with environmental regulations.

Beyond product offerings, Intensiv-Filter Himenviro provides comprehensive support services, including installation, maintenance, and troubleshooting. Their commitment to customer satisfaction and long-term partnerships sets them apart in the industry.

Key Solutions from Intensiv-Filter Himenviro:

Bag Filters:

Bag filters are a staple in the pulp and paper industry for capturing particulate matter and dust.

Intensiv-Filter Himenviro offers a diverse range of bag filter designs, each tailored to specific applications and operating conditions. Reverse air and pulse jet systems are two common types of bag filters:

- Reverse Air Bag Filters: These systems use compressed air to periodically reverse the airflow through the filter bags, dislodging the captured particles.The cleaned bags are then ready for another filtration cycle.

- Pulse Jet Bag Filters: Employing short bursts of compressed air, pulse jet systems effectively dislodge particles from the filter bags.This method is often preferred for applications with high dust loads or sticky particles.

Electrostatic Precipitators (ESPs):

Wet Scrubbers:

When dealing with gaseous pollutants and acid gases, wet scrubbers are employed.

Intensiv-Filter Himenviro offers various wet scrubber technologies, including

- Spray Towers: These systems use a spray of liquid to scrub pollutants from the gas stream.

- Packed Bed Scrubbers: Involve a packed bed of material that increases the surface area for gas-liquid contact, enhancing removal efficiency.

- Venturi Scrubbers: Generate high-velocity gas flow to create small droplets for efficient contaminant capture.

The choice of wet scrubber depends on factors such as the type of pollutant, gas flow rate, and operating conditions. Intensiv-Filter Himenviro can help select the most suitable wet scrubber technology for specific applications.

Hybrid Systems:

For complex applications that involve a combination of particulate matter and gaseous pollutants, Intensiv-Filter Himenviro can design hybrid systems that integrate multiple technologies. These systems can combine bag filters, ESPs, and wet scrubbers to achieve optimal performance and meet stringent emission requirements.

Connect with us Now

Benefits of Partnering with Intensiv-Filter Himenviro:

Intensiv-Filter Himenviro is a leading provider of industrial filtration solutions, specializing in the pulp and paper industry. They offer tailored, high-performance filtration systems that ensure air quality, reduce emissions, and enhance operational efficiency. With a focus on advanced technology and environmental sustainability, Intensiv-Filter Himenviro is a trusted partner for paper mills seeking optimal filtration solutions.

Tailored Solutions and Advanced Technology

Intensiv-Filter Himenviro stands out as a partner for the pulp and paper industry due to its commitment to providing tailored solutions and leveraging advanced technologies. The company recognizes that each paper mill has unique operational requirements and environmental challenges. Therefore, they work closely with their clients to understand their specific needs and design filtration systems that are precisely tailored to their facilities.

To ensure optimal performance and efficiency, Intensiv-Filter Himenviro utilizes the latest advancements in filtration technology and materials. Their engineers and technicians stay abreast of industry trends and incorporate innovative solutions into their designs. This commitment to cutting-edge technology enables them to deliver filtration systems that not only meet current standards but also anticipate future needs and challenges.

Comprehensive Support and Environmental Focus

Intensiv-Filter Himenviro offers more than just products; they provide comprehensive support throughout the project lifecycle. From initial consultation and design to installation, commissioning, and ongoing maintenance, their team of experienced professionals is dedicated to ensuring customer satisfaction. This level of support is invaluable in minimizing downtime and maximizing the return on investment for paper mills.

Furthermore, Intensiv-Filter Himenviro is deeply committed to environmental sustainability. Their filtration solutions are designed to help paper mills comply with stringent environmental regulations and reduce their ecological footprint. By minimizing emissions and promoting efficient resource utilization, Intensiv-Filter Himenviro contributes to a healthier planet.

Cost-Effective Solutions for Long-Term Value

While investing in filtration systems is essential, it’s equally important to ensure that the investment is cost-effective. Intensiv-Filter Himenviro focuses on providing solutions that deliver long-term value. Their designs are optimized for energy efficiency, reducing operating costs and minimizing maintenance requirements. Additionally, their focus on quality materials and construction ensures the durability of their systems, extending their lifespan and reducing the need for frequent replacements.

By partnering with Intensiv-Filter Himenviro, pulp and paper mills can benefit from tailored solutions, advanced technology, comprehensive support, and a commitment to environmental sustainability. This collaboration enables them to improve air quality, reduce emissions, enhance operational efficiency, and contribute to a more sustainable future.

Conclusion

Filtration stands as a cornerstone of the pulp and paper industry, significantly impacting product quality, process efficiency, and environmental sustainability. From the initial removal of impurities in the pulping process to the fine-tuning of paper coatings, filtration plays a pivotal role. While challenges such as high solids content, abrasive particles, and fiber clogging exist, advancements in filtration technology, including self-cleaning filters, membrane filtration, and optimized filter media, have addressed these issues to a large extent.

The future of pulp and paper filtration is bright, with a focus on energy efficiency, sustainability, and automation. By continuously developing and implementing innovative filtration solutions, the industry can optimize resource utilization, reduce environmental impact, and produce high-quality paper products that meet the demands of a growing and increasingly eco-conscious global market.

Ultimately, filtration is not merely a technical process but a strategic investment in the long-term success and sustainability of the pulp and paper industry.