Tackling Air Pollution with Innovative Solutions

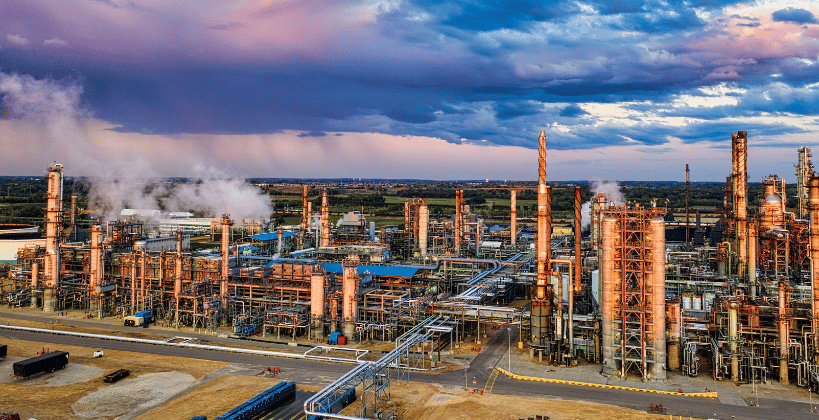

Air pollution is a global environmental challenge, directly impacting ecosystems, human health, and the climate. Industrial emissions are among the primary contributors to air pollution, producing hazardous substances like particulate matter, volatile organic compounds (VOCs), and harmful gases. As industries grow, governments and environmental organizations worldwide have imposed stricter regulations to control and reduce these emissions.

This has led to an increased reliance on air pollution control equipment—systems specifically designed to minimize pollutants released into the atmosphere during industrial processes. These technologies have become essential not only for environmental protection but also for maintaining industrial compliance and operational efficiency.

In this blog, we will discuss the growing importance of air pollution control equipment, the various types available, their applications, and the unique solutions offered by Intensiv-Filter Himenviro.

The Importance of Air Pollution Control Equipment

Industries such as cement production, metal smelting, chemical processing, and power generation are among the largest contributors to air pollution due to their high levels of emissions. These emissions, if left unchecked, can result in a multitude of severe environmental and health-related consequences, such as:

Global Warming and Climate Change: The release of greenhouse gases, such as carbon dioxide (CO2) and methane (CH4), significantly contributes to global warming, leading to rising temperatures, melting glaciers, sea-level rise, and increasingly erratic weather patterns.

Health Hazards for Local Communities: Air pollutants like particulate matter (PM), sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs) can cause a range of respiratory illnesses, cardiovascular diseases, and other long-term health complications for people living near industrial facilities. Prolonged exposure to polluted air has also been linked to reduced life expectancy.

Environmental Contamination: Airborne pollutants can settle on soil, water bodies, and vegetation, leading to contamination that adversely impacts agricultural productivity, potable water quality, and natural ecosystems. Toxic substances can enter the food chain, posing additional risks to both wildlife and human populations.

Loss of Biodiversity and Ecosystem Disruption: High levels of air pollution can damage ecosystems, reducing biodiversity by affecting the health and reproductive capabilities of plants and animals. Acid rain, a byproduct of air pollution, can severely degrade forests, aquatic ecosystems, and soil fertility, upsetting the balance of entire ecosystems.

Considering these significant challenges, the deployment of air pollution control equipment has become a critical component of industrial operations. Beyond merely meeting regulatory compliance, investing in pollution control technologies demonstrates a commitment to sustainable and ethical practices. It not only helps mitigate the environmental impact of industrial processes but also protects public health and supports the preservation of natural ecosystems, ensuring a better quality of life for current and future generations.

Key Benefits of Air Pollution Control Equipment

- Pagsunod sa Regulasyon:

Stringent laws and regulations mandate industries to limit their emissions. Non-compliance can result in hefty fines, operational shutdowns, and reputational damage. - Proteksyon sa kapaligiran:

By capturing and neutralizing harmful pollutants, these systems prevent environmental degradation and promote sustainability. - Worker Health and Safety:

Cleaner air within industrial facilities reduces occupational health risks and improves worker productivity. - Cost Efficiency:

Long-term cost savings can be achieved through reduced energy consumption, lower maintenance requirements, and enhanced equipment lifespan. - Corporate Responsibility:

Implementing air pollution control measures showcases a company’s commitment to sustainable practices, improving its image among stakeholders and customers.

Tuklasin ang Aming Saklaw ng Mga Solusyon:

Types of Air Pollution Control Equipment

Air pollution control equipment is tailored to address specific types of pollutants and industrial processes. Let’s explore the most commonly used technologies:

1. Electrostatic Precipitators (ESPs)

Electrostatic precipitators (ESPs) are advanced air pollution control devices that efficiently remove fine particulate matter from industrial flue gases. By capturing dust, ash, and other particles, ESPs play a critical role in reducing emissions and ensuring compliance with environmental standards. Their capacity to handle large gas volumes makes them indispensable for high-emission industries.

How It Works:

ESPs operate by ionizing pollutants in the gas stream using an electric field. The charged particles adhere to oppositely charged collection plates. Periodic cleaning, such as mechanical rapping, removes accumulated particles, while the cleaned flue gas is safely released into the atmosphere.

Mga Application:

ESPs are widely used in:

- Mga halamang semento: Removing dust from clinker production.

- Thermal Power Plants: Capturing fly ash from coal combustion.

- Steel Facilities: Controlling emissions during smelting and rolling.

Mga kalamangan:

With exceptional high efficiency, this solution captures up to 99% of fine particulates, including ultrafine particles, ensuring superior air quality. Its minimal pressure drop design guarantees low energy loss, resulting in significant cost savings. The system demonstrates remarkable adaptability, effectively handling large gas volumes, making it suitable for diverse industrial applications. Built for durability, it withstands harsh industrial conditions, ensuring reliable, long-term performance.

2. Baghouse Filters

Baghouse filters are highly efficient air pollution control devices that use fabric filter bags to capture dust and particulates from industrial emissions. They are versatile and widely used across industries to maintain air quality and meet environmental regulations.

How It Works:

Polluted air passes through fabric filters inside the baghouse. The filters trap dust and particulates while allowing clean air to pass through. Periodic cleaning mechanisms, such as shaking or reverse air pulses, remove the accumulated particles from the filters, ensuring consistent performance.

Mga Application:

Baghouse filters are commonly used in:

- Chemical Plants: Controlling emissions from chemical processing.

- Mining Operations: Capturing dust from material handling and processing.

- Woodworking Industries: Removing fine sawdust and wood particles.

Mga kalamangan:

- High Collection Efficiency: Effectively traps particles of various sizes, ensuring clean air.

- Low Operational Costs: Simple design and maintenance make baghouse filters cost-effective.

- Kakayahang magamit: Suitable for a wide range of applications and industries.

3. Scrubbers

Scrubbers are versatile air pollution control systems that effectively remove gases and particulates from industrial emissions using liquid or chemical solutions. They are widely adopted for controlling harmful emissions and ensuring compliance with environmental standards.

How It Works:

Scrubbers operate by bringing polluted gas streams into contact with a scrubbing liquid, such as water or a chemical solution. The pollutants are either absorbed or chemically neutralized during this process. The treated gas is then released, while the captured pollutants are collected for disposal or further treatment.

Mga Application:

Scrubbers are commonly utilized in:

- Waste Incineration: Controlling toxic emissions from burning waste.

- Pagproseso ng Kemikal: Removing harmful gases during manufacturing processes.

- Oil Refineries: Managing emissions from refining crude oil.

Mga kalamangan:

- Effective Gas Removal: Efficiently removes gas-phase pollutants like sulfur dioxide (SO₂) and nitrogen oxides (NOₓ).

- Kakayahang magamit: Can handle a wide variety of pollutants and emission sources.

- Customizability: Adaptable to meet specific industry and regulatory requirements.

4. Hybrid Systems

Hybrid systems combine multiple air pollution control technologies, such as Electrostatic Precipitators (ESPs) and bag filters, to provide comprehensive solutions for managing complex emissions. These systems are ideal for industries with diverse pollutants that require versatile and efficient treatment methods.

How It Works:

Hybrid systems integrate different pollution control technologies, allowing them to target a wide range of pollutants in a single setup. For instance, an ESP may capture fine particulates, while a bag filter removes larger particles, ensuring thorough filtration and efficient emission control.

Mga Application:

Hybrid systems are commonly used in:

- Industries with Complex Emissions: Handling multiple types of pollutants from processes like cement production, steel manufacturing, and chemical processing.

- Large-Scale Operations: Environments where diverse pollutant sources need to be managed simultaneously.

Mga kalamangan:

- Mataas na Kahusayan: Combines the strengths of multiple technologies to achieve superior particulate and gas-phase pollutant removal.

- Kakayahang umangkop: Tailored to handle varying types and volumes of emissions.

- Pinababang Pagkonsumo ng Enerhiya: By integrating complementary technologies, hybrid systems optimize energy use and lower operational costs.

Kumonekta sa amin Ngayon

Applications of Air Pollution Control Equipment

Air pollution control equipment is crucial across various industries, each facing unique challenges and requirements. In cement production, large amounts of dust and particulate matter are released during clinker production and material handling, with technologies like Electrostatic Precipitators (ESPs) and baghouse filters ensuring compliance with emission standards. In power generation, thermal power plants emit fly ash, sulfur dioxide (SO₂), and nitrogen oxides (NOₓ), which require advanced systems such as scrubbers and ESPs to mitigate their environmental impact. Chemical processing industries generate volatile organic compounds (VOCs) and hazardous gases during manufacturing, for which activated carbon filters and scrubbers are ideal solutions. Metal smelting and refining processes, such as smelting and casting, release fine particulates and toxic gases, and are typically managed with cyclone separators and baghouse filters. The food and beverage industry uses air pollution control systems to manage odors, steam, and particulate emissions, ensuring a hygienic and safe production environment. Lastly, in waste management, incinerators and landfill gas recovery systems rely on scrubbers and activated carbon filters to effectively manage emissions and odors. These diverse applications highlight the importance of tailored air pollution control solutions across industries to meet environmental regulations and ensure cleaner operations.

How Intensiv-Filter Himenviro Leads the Industry

Intensiv-Filter Himenviro is a global leader in providing innovative air pollution control solutions tailored to meet the specific needs of various industries.

Our systems are designed to comply with stringent regulatory requirements while enhancing operational efficiency. We leverage cutting-edge technologies, such as IoT-enabled monitoring, AI integration, and hybrid designs, to ensure maximum performance and reliability. Our approach includes close collaboration with clients to design custom solutions that address their unique process requirements and challenges. With a strong focus on sustainability, we prioritize energy efficiency, resource conservation, and minimizing environmental impact in all our solutions.

Additionally, we offer comprehensive support throughout the entire lifecycle of our products, from installation to ongoing maintenance, ensuring smooth and reliable operations. Our extensive product portfolio includes Electrostatic Precipitators (ESPs), bag filters, scrubbers, and hybrid systems, serving a wide range of industrial applications and helping industries maintain clean and compliant operations.

Future Trends in Air Pollution Control

As industries continue to evolve, air pollution control technologies are advancing to meet new challenges. One of the key trends is the integration of digitalization and the Internet of Things (IoT) into these systems. IoT-enabled solutions enable real-time monitoring, predictive maintenance, and optimized performance, enhancing the overall effectiveness of air pollution control equipment.

Another significant development is the use of Artificial Intelligence (AI) in air pollution control systems. AI-driven algorithms are increasingly being used to improve equipment efficiency by analyzing data and automating adjustments, ensuring that the systems adapt to varying conditions for optimal performance.

Additionally, carbon capture and storage technologies are gaining importance as industries strive toward carbon neutrality. Innovative solutions for capturing and storing CO2 are becoming more prevalent, helping to reduce emissions and contribute to environmental sustainability.

The growing demand for environmentally friendly practices is also reflected in the materials used in air pollution control equipment. Eco-friendly materials, particularly recyclable and sustainable options, are being increasingly incorporated into equipment design, aligning with broader sustainability goals.

Lastly, modular designs are revolutionizing air pollution control systems. These systems offer flexibility and scalability, making them ideal for industries with dynamic production needs. Modular systems allow for easier upgrades and modifications, providing businesses with the ability to adapt their equipment to changing environmental regulations and production demands.

Conclusion: Building a Sustainable Future

Air pollution control equipment is more than just an industrial necessity; it’s a commitment to environmental stewardship and sustainable growth. By investing in advanced solutions from Intensiv-Filter Himenviro, industries can not only achieve regulatory compliance but also contribute to a cleaner, healthier planet.

Let us partner with you in creating innovative, reliable, and sustainable air pollution control systems tailored to your needs. Together, we can ensure a future where industrial progress and environmental responsibility go hand in hand.